Crusher:The Olive’s Journey to Extra Virgin Olive Oil

The oil mill is the heart of the extra virgin olive oil supply chain: this is where theolive is transformed into EVO oil. The oil mill is the place where artisan skills and technological innovation meet to obtain an authentic product of excellence.

The process begins with the olive harvest, which takes place at the right degree of ripeness. The olives are transferred quickly to the mill (within 12-24 hours) to avoid oxidation or fermentation phenomena.

Index

Processing stages in the mill: from harvesting to milling

- Selection and washing: olives are freed from leaves and branches, then washed thoroughly.

- Milling: Crushing is done with mechanical crushers or stone grinders. An olive paste is thus obtained.

- Gramolatura: the paste is stirred to facilitate the joining of the oil drops.

- Extraction:

- In continuous cycle mills, centrifugation is used;

- In traditional mills, pressing can be done by pressure.

- Separation and filtration: oil is separated from water and pomace, filtered and then stored in stainless steel tanks.

All these steps take place at low temperature (maximum 27 °C), according to the cold-pressing technique, to preserve polyphenols, antioxidants and fragrances.

Read also: Olive yield: what it’s all about.

Contedoro oil mill: innovation and territory

Contedoro’s modern olive mill is equipped with advanced technologies such as hammer crushers, temperature-controlled crushers and centrifugal separators. We process Irpinia olives hand-picked and pressed within 24 hours to produce an extra virgin olive oil with a rich and balanced organoleptic profile.

Every detail is taken care of to preserve herbaceous hints, fruity taste, the right degree of bitterness and spiciness, and a high concentration of polyphenols.

The miller: the guardian of quality

The olive miller is the central figure within the mill. He oversees every step, from pressing the olives to crushing, ensuring that temperatures, timing and process parameters are always under control. His experience is what distinguishes a good oil from an extraordinary oil.

Conclusion: the olive mill, a garrison of excellence

Whether traditional mills or modern mills, every step within the oil mill contributes to the creation of a superior extra virgin olive oil. Respect for the raw material, the use of careful processing techniques, and the careful work of the miller are what make an oil truly worthy of the Italian tradition.

At Contedoro, each drop tells a story of commitment, territory and passion forextra virgin olive oil. If you would like to learn more about our production method or buy authentic, quality oil, visit our e-commerce or contact us directly.

-

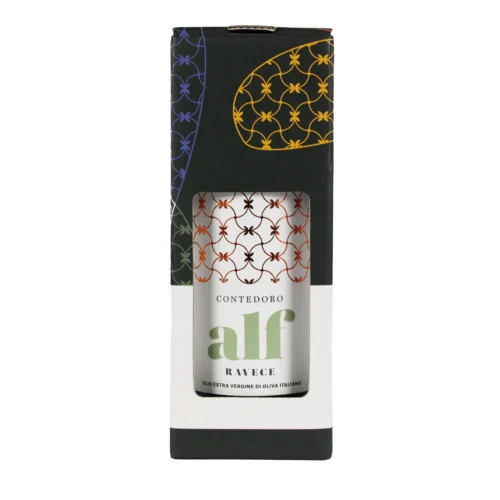

ALF – Ravece Selection16,00€

ALF – Ravece Selection16,00€ -

Raw Oil – Unfiltered EVO 0.50 and 5Lt.9,00€

Raw Oil – Unfiltered EVO 0.50 and 5Lt.9,00€ -

GOLD selection13,00€

GOLD selection13,00€ -

Oil Ravece12,00€

Oil Ravece12,00€ -

Oil Ravece7,80€

Oil Ravece7,80€ -

Organic Extra Virgin Olive Oil6,80€

Organic Extra Virgin Olive Oil6,80€ -

Basil-flavored extra virgin olive oil8,50€

Basil-flavored extra virgin olive oil8,50€ -

Lemon-flavored extra virgin olive oil8,50€

Lemon-flavored extra virgin olive oil8,50€ -

Chili pepper flavored extra virgin olive oil8,50€

Chili pepper flavored extra virgin olive oil8,50€

-

Olive Oil Specific Weight, What It Is and How It Is Calculated

Reading time: 5 minutes Specific gravity is a value that can be calculated for all materials, both solid and liquid. However, this measurement is, for some elements, more or less important. In our case, it is very important to know the specific gravity of olive oil. We will see below why. Here we want to…

-

Olio EVO Price, Here’s the Cost of Italian EVO Oil.

Extra virgin olive oil is one of the most popular ingredients in Italian cuisine and a symbol of quality and Mediterranean tradition. But what is the price of EV O oil today? And why are there such marked price differences between one product and another? In this article you’ll find out everything you need to…

Alfio Lo Conte

Tecnico ed esperto degli oli extravergini di oliva, iscritto nell’Elenco Nazionale sezione Campania.

Maestro di frantoio con diploma, conseguito presso International Extravirgin Agency.

Read more articles by: Alfio Lo Conte

Recent Comments